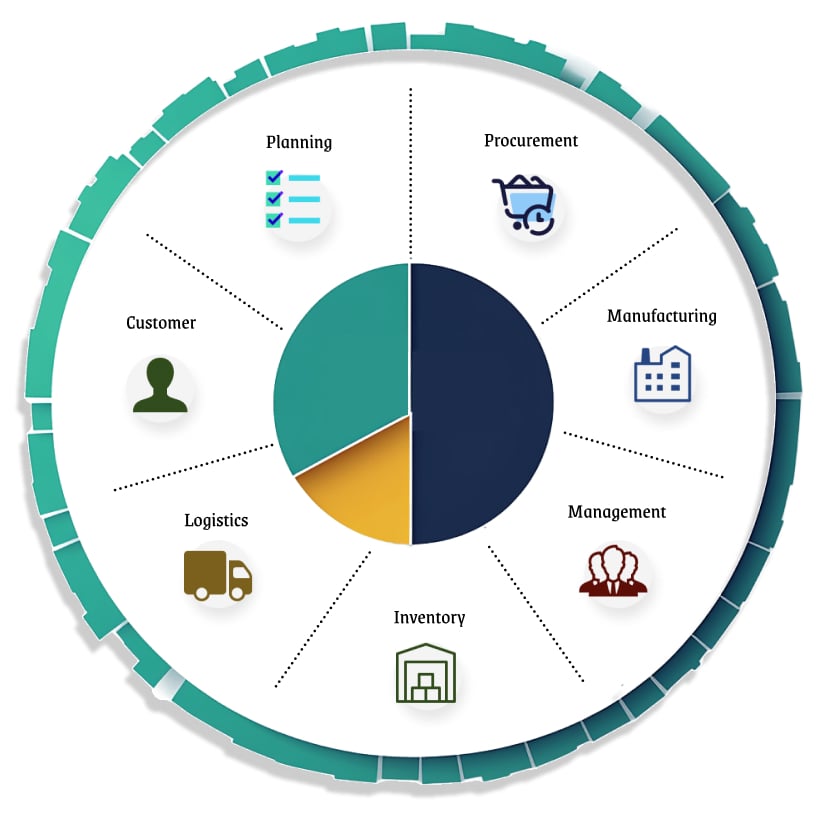

Our sourcing and procurement services streamline your access to top-quality parts for your projects.

Leveraging our extensive network to find even the elusive components, ensuring your production remains on schedule with competitive pricing.

By building strong, collaborative relationships with our key suppliers we foster better communication, better quality and services and cost competitiveness. We engage reliable couriers to ensure timely delivery.

We use the Manufacturing Execution System for incoming PCB inspection and monitoring orders to generate IMI checklist reports. Information such as vendors’ names, project details and defects are being reflected in the report to ensures quality control, efficiency, and transparency in our operations.

We use Enterprise Resource Planning System for monitoring orders and inventory to capture real-time data integration, enhancing visibility and streamline the operations. Conducting weekly counts to check shelf life and inventory levels for maintaining optimal stock levels and reducing holding costs while meeting customers’ needs and demands.

Explore our mechanical solutions with advanced 3D modeling, rapid prototyping, and careful material selection.

Discover our advanced electrical designs with accurate schematics, quality components, and thorough testing.

Explore our innovative software and integrated systems, designed for reliability, high performance, and smooth hardware-software integration.

Discover our PCB assembly process, from sourcing components to quality control, integration, and box build.

© 2025 Glendale Electronic Components Pte Ltd. All rights reserved.